Cryogenic Planetary Ball Mill

- Model No.:XQM-1(C)

- Brand:TENCAN

- Applications:Cryogenic planetary ball mill is mainly applied to ultrafine grinding under condition of low-temperature requested by materials. Compared with the artificial injection of liquid nitrogen cooling, cold-air planetary ball mill is much easier and more convenient to be operated, it is also cost-saved, and low-energy consumed.

Overview

Overview

Cold-air planetary ball mill is composed of planetary ball mill and cold-air device. Cycling of cold air quickly takes away the heat generated by grinding by means of air conditioning refrigeration principle, and temperature inside the grinding space can be controlled at 2-10 ℃ according to temperature difference of working environment. Such a cold-air device can be also applied to assembly other models like vertical ball mill, horizontal ball mill, 360 degree ball mill and dual ball mill.

Working Principle

Working Principle

XQM series planetary ball mill has four ball grinding tanks installed on one turntable. When the turntable rotates, the tank axis makes planetary movements and the balls in the tanks grinds and mixes samples in high speed movement. The product can smash and blend various products of different materials and granularity with dry or wet methods. Minimum granularity of ground powder can be as small as 0.1mm.

XQM series planetary ball mill has four ball grinding tanks installed on one turntable. When the turntable rotates, the tank axis makes planetary movements and the balls in the tanks grinds and mixes samples in high speed movement. The product can smash and blend various products of different materials and granularity with dry or wet methods. Minimum granularity of ground powder can be as small as 0.1mm.

Feature

Features

1.powerful and quick grinding down to nano range

2.comfortable parameter setting via display and ergonomic 1-button operation

3.automatic grinding chamber ventilation

1.powerful and quick grinding down to nano range

2.comfortable parameter setting via display and ergonomic 1-button operation

3.automatic grinding chamber ventilation

Technical Parameter

Technical Parameter

| Parameter 1 | ||||

| Model | Volume of Jar(L) | Dimension(mm) | Maximum Rotating Speed(rpm) | Power (KW) |

| XQM-1(C) | 1 | 730*430*580 | 670 | 0.75 |

| XQM-2(C) | 2 | 730*430*580 | 670 | 0.75 |

| XQM-4(C) | 4 | 800*470*560 | 670 | 0.75 |

| XQM-8(C) | 8 | 880*600*640 | 580 | 1.5 |

| XQM-12(C) | 12 | 880*600*640 | 580 | 1.5 |

| XQM-16(C) | 16 | 950*600*680 | 510 | 3 |

| XQM-20(C) | 20 | 1200*760*750 | 430 | 4 |

| XQM-40(C) | 40 | 1300*870*830 | 390 | 5.5 |

| XQM-60(C) | 60 | 1500*950*1000 | 360 | 7.5 |

| XQM-100(C) | 100 | 1750*1100*1350 | 240 | 11 |

| Max. Continuous Operating Time: 72 hours | ||||

| Parameter 2 | ||||

| Model | Volume of Jar(L) | Dimension(mm) | Maximum Rotating Speed(rpm) | Power (KW) |

| QXQM-1(C) | 1 | 1100*750*825 | 670 | 0.75 |

| QXQM-2(C) | 2 | 1100*750*825 | 670 | 0.75 |

| QXQM-4(C) | 4 | 1100*750*825 | 670 | 0.75 |

| QXQM-6(C) | 6 | 1100*750*825 | 670 | 0.75 |

| QXQM-8(C) | 8 | 1220*900*960 | 580 | 1.5 |

| QXQM-10(C) | 10 | 1220*900*960 | 580 | 1.5 |

| QXQM-12(C) | 12 | 1220*900*960 | 580 | 1.5 |

| QXQM-16(C) | 16 | 1530*1070*1220 | 510 | 3 |

| Max. Continuous Operating Time: 48 hours | ||||

| Parameter 3 | ||||

| Model | Volume of Jar(L) | Dimension(mm) | Maximum Rotating Speed(rpm) | Power (KW) |

| WXQM-1(C) | 1 | 560*470*730 | 670 | 0.75 |

| WXQM-2(C) | 2 | 560*470*730 | 670 | 0.75 |

| WXQM-4(C) | 4 | 560*470*730 | 670 | 0.75 |

| WXQM-6(C) | 6 | 1050*730*810 | 670 | 0.75 |

| WXQM-8(C) | 8 | 1050*570*700 | 580 | 1.5 |

| WXQM-10(C) | 10 | 1050*570*700 | 580 | 1.5 |

| WXQM-12(C) | 12 | 1050*570*700 | 580 | 1.5 |

| WXQM-16(C) | 16 | 1260*640*780 | 480 | 3 |

| WXQM-20(C) | 20 | 1500*700*850 | 430 | 4 |

| WXQM-40(C) | 40 | 1500*770*900 | 430 | 5.5 |

| WXQM-60(C) | 60 | 1530*900*1020 | 420 | 7.5 |

| WXQM-80(C) | 80 | 1750*990*1130 | 420 | 11 |

| Max. Continuous Operating Time: 72 hours | ||||

| Parameter 4 | ||||

| Model | Volume of Jar(L) | Dimension(mm) | Maximum Rotating Speed(rpm) | Power (KW) |

| SXQM-0.4(C) | 0.4 | 910*660*630 | 1340 | 0.75 |

| SXQM-1(C) | 1 | 910*660*630 | 1340 | 0.75 |

| SXQM-2(C) | 2 | 910*660*630 | 1340 | 0.75 |

| SXQM-4(C) | 4 | 910*660*630 | 1340 | 0.75 |

| SXQM-6(C) | 6 | 910*660*630 | 1340 | 0.75 |

| Max. Continuous Operating Time: 72 hours | ||||

| Parameter 5 | |

| Drive Mode | Gear drive and belt drive |

| Operation Mode | Two or four grinding tanks working together |

| Maximum Loading Capacity | 2/3 of the capacity of milling tank |

| Feeding Size | Soil material≤10mm, other materials≤3mm |

| Output Granularity | Minimum 0.1 μm |

| Rotational Speed Ratio | 1/2 |

| Max. Continuous Operating Time | 72hours |

| Materials of Jar | Stainless steel, agate, nylon, corundum, zirconia, etc. |

Accessory

Accessory

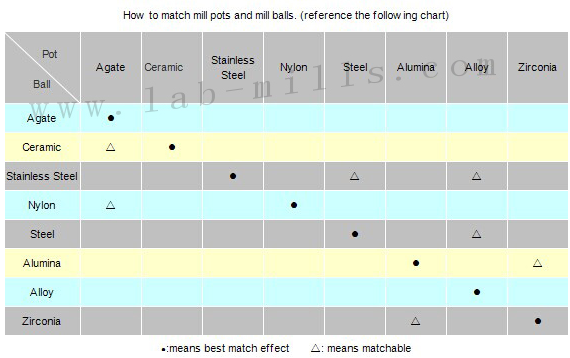

Besides the planetary ball mill machine, our factory provides all kinds of mill pots stainless steel pot, zirconia pot, alumina pot, nylon pot, PU pot, tungsten pot, hard metal pot tempered nylon pot etc. Further, we also provide stainless steel balls, zirconia balls, alumina balls, PU balls, steel carbon balls, tungsten balls, etc.

Besides the planetary ball mill machine, our factory provides all kinds of mill pots stainless steel pot, zirconia pot, alumina pot, nylon pot, PU pot, tungsten pot, hard metal pot tempered nylon pot etc. Further, we also provide stainless steel balls, zirconia balls, alumina balls, PU balls, steel carbon balls, tungsten balls, etc.

Mill Pots

We provide all kinds of mill pots in any matched size, which are made from following materials of agate, Alumina corundum ceramics, zirconia ceramics, silicon nitride ceramics, carborundum ceramics, stainless steel, high wear resistant steel, manganese steel, nylon, PU, cemented carbide, crystal glass, and etc.

Mill Balls

We can also provide all kinds of mill balls like stainless steel balls, zirconia balls, alumina balls, PU balls, steel carbon balls, tungsten balls, agate balls, hard metal balls, silicon nitride balls, high wear resistant steel ball, manganese steel balls, nylon balls, polytef , cemented carbide, crystal glass and other special metal materials.

We can also provide all kinds of mill balls like stainless steel balls, zirconia balls, alumina balls, PU balls, steel carbon balls, tungsten balls, agate balls, hard metal balls, silicon nitride balls, high wear resistant steel ball, manganese steel balls, nylon balls, polytef , cemented carbide, crystal glass and other special metal materials.