Full-Directional Planetary Ball Mill

- Model No. :QXQM-1

- Brand:TENCAN

- Applications:QXQM series planetary ball mill is the requisite equipment for mixing, fine grinding, small sample preparing, new product development and small volume high-tech material production. The product has small volume, complete function, high efficiency and low noise. It is the ideal facility to acquire research samples for research institutes, universities as well as enterprise laboratories (can acquire four samples in one experiment).

Overview

Overview

It is widely used in the area of geology, mine, metallurgy, electric industry, construction, ceramics, chemicals, light industry, medicine, environmental protection etc. It plays an important role in the production of electronic ceramics, structural ceramics, magnetic materials, LCO, LMO, catalyst, fluorescent powder, glass powder, fuel cell, zinc oxide varistor, piezoelectric ceramics, nano meter materials, MLCC, PTC, NTC, media ceramics, fluorescent powder etc.

It is widely used in the area of geology, mine, metallurgy, electric industry, construction, ceramics, chemicals, light industry, medicine, environmental protection etc. It plays an important role in the production of electronic ceramics, structural ceramics, magnetic materials, LCO, LMO, catalyst, fluorescent powder, glass powder, fuel cell, zinc oxide varistor, piezoelectric ceramics, nano meter materials, MLCC, PTC, NTC, media ceramics, fluorescent powder etc.

Working Principle

Working Principle

QXQM series planetary ball mill has four ball grinding tanks installed on one disc. When the turn disc rotates, the mill pots revolve on their own axis and make 360 degree rotation. And the balls in the tanks grind and mix samples in high speed movement. The product can smash and blend various products of different materials and granularity with dry or wet methods. Minimum granularity of ground samples can be as small as 0.1 micron meter. It is widely used in the fields of Geology, Mining, Metallurgy, Electronics, Construction Material, Ceramics, Chemical Engineering, Light Industry Medicine, Environmental Protection etc.

QXQM series planetary ball mill has four ball grinding tanks installed on one disc. When the turn disc rotates, the mill pots revolve on their own axis and make 360 degree rotation. And the balls in the tanks grind and mix samples in high speed movement. The product can smash and blend various products of different materials and granularity with dry or wet methods. Minimum granularity of ground samples can be as small as 0.1 micron meter. It is widely used in the fields of Geology, Mining, Metallurgy, Electronics, Construction Material, Ceramics, Chemical Engineering, Light Industry Medicine, Environmental Protection etc.

Advantages

A wide range of powder can be ground by our planetary ball mill with different mill jars and balls, such as ore powder, fluorescent powder, glass powder, pigment powder and so on. Following are some powder samples for your reference.

Feature

Features

1.The machine makes 360 degree planetary movement without any dead corner, so the ground powder is much smaller and more even

2. Gear transmission ensures to keep consistency and repeatability of experiment.

3. You may get four different powder samples at one time.

4. Variable frequency controlled and program controlled.

5. It solves the problems of materials sinking and sticking to the pot.

Technical Features

1.The machine makes 360 degree planetary movement without any dead corner, so the ground powder is much smaller and more even

2. Gear transmission ensures to keep consistency and repeatability of experiment.

3. You may get four different powder samples at one time.

4. Variable frequency controlled and program controlled.

5. It solves the problems of materials sinking and sticking to the pot.

Technical Features

| Drive Mode | Gear drive and belt drive |

| Operate Mode | Two or four grinding tanks working together |

| Maximum Loading Capacity | 2/3 of the capacity of milling tank |

| Feeding Size | Soil material≦10mm,other materials≦3mm |

| Output Granularity | Minimum 0.1μm |

| Rotational Speed Ratio | /1/2 |

| Max.Continuous Operating Time | 48hours |

| Materials of Jar | stainless steel.agate,nylon,corundum,zirconia,etc |

Technical Parameter

Technical Parameter

| Parameters of Full-Directional Planetary Ball | |||

| Type | Dimension(mm) | Maximum Rotating Speed(rpm) | Power(KW) |

| QXQM-0.4 | 960*480*520 | 870 | 0.25 |

| QXQM-1 | 1100*750*825 | 670 | 0.75 |

| QXQM-2 | 1100*750*825 | 670 | 0.75 |

| QXQM-4 | 1100*750*825 | 670 | 0.75 |

| QXQM-6 | 1100*750*825 | 670 | 0.75 |

| QXQM-8 | 1290*750*830 | 580 | 1.5 |

| QXQM-10 | 1290*750*830 | 580 | 1.5 |

| QXQM-12 | 1290*750*830 | 580 | 1.5 |

| QXQM-16 | 1370*1000*990 | 510 | 3 |

| QXQM-20 | 1700*1100*1200 | 430 | 4 |

| QXQM-40 | 1850*1300*1400 | 390 | 5.5 |

Accessory

Planetary Ball Mill Accessories - Mill Pots and Mills Balls

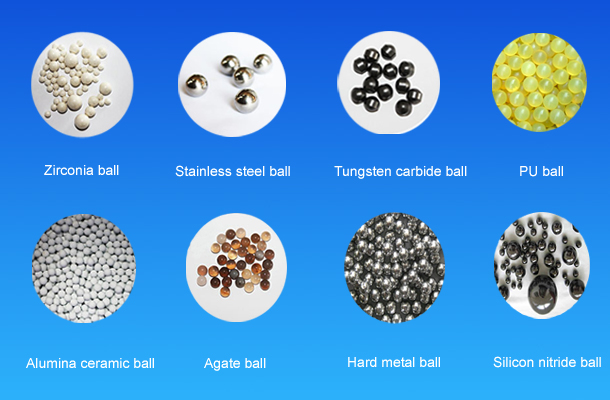

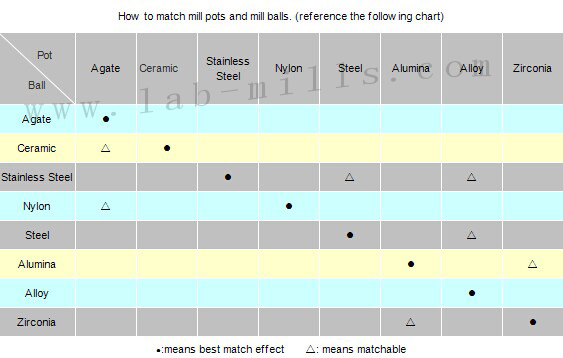

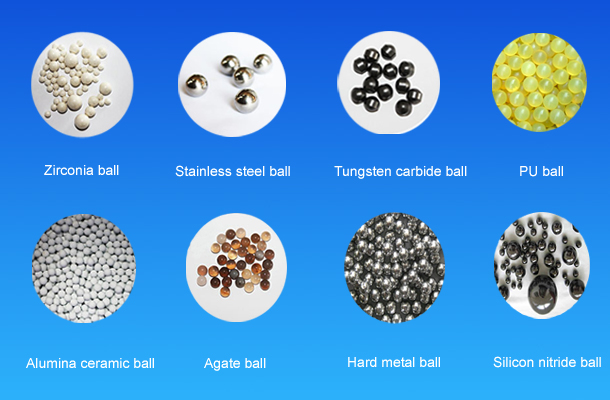

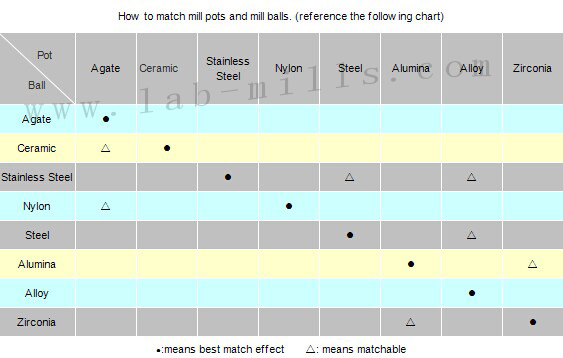

Besides the planetary ball mill machine, our factory provides all kinds of mill pots stainless steel pot, zirconia pot, alumina pot, nylon pot, PU pot, tungsten pot, hard metal pot, tempered nylon pot etc. Further, we also provide stainless steel balls, zirconia balls, alumina balls, PU balls, steel carbon balls, tungsten balls, etc. Mill pots

Mill pots

We provide all kinds of mill pots in any matched size, which are made from the following materials of agate, Alumina corundum ceramics, zirconia ceramics, silicon nitride ceramics, carborundum ceramics, stainless steel, high wear resistant steel, manganese steel, nylon, PU, cemented carbide, crystal glass, and etc.

Besides the planetary ball mill machine, our factory provides all kinds of mill pots stainless steel pot, zirconia pot, alumina pot, nylon pot, PU pot, tungsten pot, hard metal pot, tempered nylon pot etc. Further, we also provide stainless steel balls, zirconia balls, alumina balls, PU balls, steel carbon balls, tungsten balls, etc.

We provide all kinds of mill pots in any matched size, which are made from the following materials of agate, Alumina corundum ceramics, zirconia ceramics, silicon nitride ceramics, carborundum ceramics, stainless steel, high wear resistant steel, manganese steel, nylon, PU, cemented carbide, crystal glass, and etc.

Mill balls

We can also provide all kinds of mill balls like stainless steel balls, zirconia balls, alumina balls, PU balls, steel carbon balls, tungsten balls, agate balls, hard metal balls, silicon nitride balls, high wear resistant steel ball, manganese steel balls, nylon balls, cemented carbide, crystal glass and other special metal materials.

We can also provide all kinds of mill balls like stainless steel balls, zirconia balls, alumina balls, PU balls, steel carbon balls, tungsten balls, agate balls, hard metal balls, silicon nitride balls, high wear resistant steel ball, manganese steel balls, nylon balls, cemented carbide, crystal glass and other special metal materials.