Vertical Planetary Ball Mill

- Model No.:XQM-2A

- Brand:TENCAN

- Applications:The planetary ball mill is widely used in many fields of geology, mine, metallurgy, electric industry, construction, ceramics, chemicals, light industry, medicine, environmental protection etc.

Overview

Vertical planetary ball mill is a necessary device of high-tech materials mixing, fine grinding, sample making, new product development and small batch production. Tencan planetary ball mill owns small volume, high efficiency, low noise and functional features which is a ideal equipment for R&D institution, university, enterprises laboratory to get samples (each experiment can get four samples at the same time). It gets powder samples under the vacuum state when equipped with vacuum ball mill jar.

Vertical planetary ball mill production model is a large-sized planetary ball mill which is designed,Developed, and manufactured on the basis of working principle of small planetary ball mill. The

production planetary ball mill is mainly suitable for mass grinding production.

Working Principle

Working Principle

Vertical Planetary Ball Mill has four ball grinding tanks installed on one turntable. When the turntable rotates, the tank axis makes planetary movements, the balls and samples inside the tanks are impacted strongly in high speed movement, and samples are eventually ground into powder. Various kinds of different materials can be ground by the mill with dry or wet method. Minimum granularity of ground powder can be as small as 0.1μm.

Advantages

1.Stable revolving speed of the gear transmission ensures the consistency and repeatability of the experiment.

2.Planetary movement principle is adopted in the machine, which has high speed, large energy, high efficiency, small Granularity.

3.Four powder samples from different sizes and different materials can be produced at one time.

4.The machine is controlled by frequency converter; you may choose ideal rotating speed according to expected experimental result. The converter is equipped with device of under voltage and over-current to protect the motor.

5.The planetary ball mill has functions of timing power off, self-timing forward and reversal rotating. You may choose freely any operation modes of one-way direction, alternation, succession, timing setting according to experimental needs, so as to improve efficiency of grinding.

6.Technical features of Tencan Ball Mill: Low center of gravity, stable performance, compact structure, easy operation, reliable safety, lower noise, small loss.

7. Safety switch is installed on the machine to prevent safety accident if the safety cover is opened while machine is running.

Feature

Features

The ball mill shell is welded with thick steel plate, which has high strength, impact resistance, deformation resistance, fine workmanship, strong and beautiful appearance. The material of mechanic parts is strictly processed by heat treatment process and numerical control processing technology. The gear box is adopted with quasi-sealed groove embedded structure, and the drive gear is made of wear-resistant precision gear. The machine frame and structure are fully considered in design to ensure the stable, safe and reliable operation of the ball mill under long-term and high load conditions, and to effectively achieve the effect of noise reduction in the operation of the machine. The liquid oil self-lubricating device is designed with low noise and high intensity, and it is equipped with a liquid oil level meter for easy replacement. The supporting lifting and feeding devices are adopted with integrated design. The feeding device incorporates the technology of vibrating screening and discharging for simple and convenient operation. It realizes easy and fast picking up, discharging and loading of mill jars, reduces labor intensity and improves production efficiency. With the touch screen of micro-computer, machine operation is becoming convenient, the interface is more simple and intuitive,forward and reversal alternating control can be achieved easily. It owns functions of timing and power-off memory.

Advantages of Tencan Vertical Planetary Ball Mill

1.Stable revolving speed of the gear transmission ensures the consistency and repeatability of the experiment.

2. Planetary movement principle is adopted in the machine, which has high speed, large energy, high efficiency, small Granularity.

3. Four powder samples from different sizes and different materials can be produced at one time.

4. The machine is controlled by frequency converter, you may choose ideal rotating speed according to expected experimental result. The converter is equipped with device of under voltage and over-current to protect the motor.

5. The planetary ball mill has functions of timing power off, self-timing forward and reversal rotating. You may choose freely any operation modes of one-way direction, alternation, succession, time setting according to experimental needs, so as to improve efficiency of grinding.

6. Technical features of Tencan Ball Mill: Low center of gravity, stable performance, compact structure, easy operation, reliable safety, lower noise, small loss.

7. Safety switch is installed on the machine to prevent safety accident if the safety cover is opened while machine is running.

|

Drive Mode |

Gear drive |

|

Operation Mode |

Two or four mill jars can be used for each grinding |

|

Max Capacity for Materials |

Less than 1/3 of each jar volume Total max capacity: less than 1/3 of total jars volume |

|

Feed Size |

Soft and crispy materials ≤ 10mm Other hard materials ≤ 3mm |

|

Output Granularity |

Smallest granularity can be achieved to 0.1μm |

|

Rotation Speed Ratio |

1:2 |

|

Max Continuous Operating Time |

72 Hours |

|

Materials of Available Mill Jars |

304 Stainless steel, 316l stainless steel, Zirconia, Nylon, PU, Alumina ceramic (corundum), PTFE, Agate, Tungsten carbide |

Technical Parameter

|

Model No. |

Voltage |

Power |

Rotation Speed |

Noise |

|

XQM-1 |

220V-50Hz |

0.75KW |

70-670 rpm |

Less than 60db |

|

XQM-2 |

220V-50Hz |

0.75KW |

70-670 rpm |

Less than 60db |

|

XQM-4 |

220V-50Hz |

0.75KW |

70-670 rpm |

Less than 60db |

|

XQM-6 |

220V-50Hz |

0.75KW |

70-670 rpm |

Less than 60db |

|

XQM-8 |

220V-50Hz |

1.5KW |

70-580 rpm |

Less than 60db |

|

XQM-10 |

220V-50Hz |

1.5KW |

70-580 rpm |

Less than 60db |

|

XQM-12 |

220V-50Hz |

1.5KW |

70-580 rpm |

Less than 60db |

|

XQM-20 |

380V-50Hz |

4.0KW |

50-430 rpm |

Less than 65db |

|

XQM-40 |

380V-50Hz |

5.5KW |

40-390 rpm |

Less than 68db |

|

XQM-60 |

380V-50Hz |

7.5KW |

40-260 rpm |

Less than 68db |

|

XQM-100 |

380V-50Hz |

11KW |

40-260 rpm |

Less than 68db |

Table 2 Technical Parameters For Tencan Vertical Planetary Ball Mill

|

Model No. |

Speed Control |

Net Weight |

Net Dimensions |

|

XQM-1 |

Frequency Control |

93kgs |

750*470*564mm |

|

XQM-2 |

Frequency Control |

93kgs |

750*470*564mm |

|

XQM-4 |

Frequency Control |

93kgs |

750*470*564mm |

|

XQM-6 |

Frequency Control |

93kgs |

750*470*564mm |

|

XQM-8 |

Frequency Control |

150kgs |

900*600*640mm |

|

XQM-10 |

Frequency Control |

150kgs |

900*600*640mm |

|

XQM-12 |

Frequency Control |

150kgs |

900*600*640mm |

|

XQM-20 |

Frequency Control |

330kgs |

1200*750*920mm |

|

XQM-40 |

Frequency Control |

468kgs |

1400*850*1160mm |

|

XQM-60 |

Frequency Control |

900kgs |

1600*990*1250mm |

|

XQM-100 |

Frequency Control |

1250kgs |

1750*1140*1330mm |

Accessory

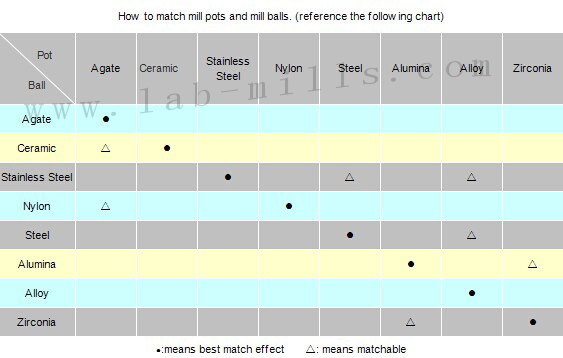

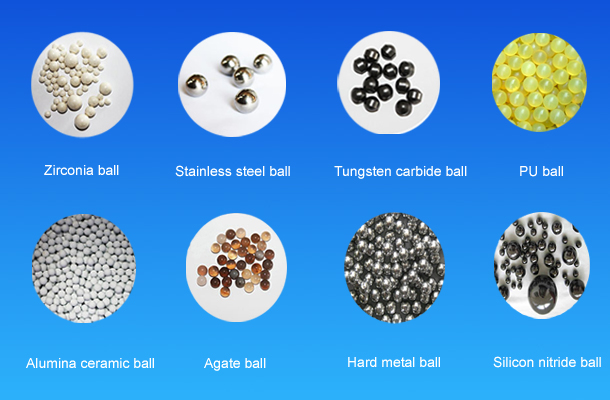

Besides the planetary ball mill machine, our factory provides all kinds of mill jars stainless steel pot, zirconia pot, alumina pot, nylon pot, PU pot, tungsten pot, hard metal pot tempered nylon pot etc. Further, we also provide stainless steel balls, zirconia balls, alumina balls, PU balls, steel carbon balls, tungsten balls, etc.

We provide all kinds of mill pots in any matched size, which are made from following materials of agate, Alumina corundum ceramics, zirconia ceramics, silicon nitride ceramics, carborundum ceramics, stainless steel, high wear resistant steel, manganese steel, nylon, PU, cemented carbide, crystal glass, and etc.

We can also provide all kinds of mill balls like stainless steel balls, zirconia balls, alumina balls, PU balls, steel carbon balls, tungsten balls, agate balls, hard metal balls, silicon nitride balls, high wear resistant steel ball, manganese steel balls, nylon balls, cemented carbide, crystal glass and other special metal materials.

|

Description of Mill Jars |

Available Specifications |

|

304 Stainless steel mill jar |

From 50ml to 25L |

|

Alumina ceramic (Corundum) mill jar |

From 50ml to 10L |

|

Zirconium mill jar |

From 50ml to 5L |

|

Nylon mill jar |

From 50ml to 25L |

|

Polyurethane mill jar |

From 50ml to 1L |

|

PTFE/Teflon mill jar |

From 50ml to 10L |

|

Agate mill jar |

From 50ml to 2L |

|

Tungsten carbide mill jar |

From 50ml to 2L |

|

316l Stainless steel mill jar |

Customized |

|

304 Stainless steel vacuum mill jar |

Customized |

Available Mill Balls & Specifications

|

Descriptions |

Available Specifications (Diameter Size) |

|

304 Stainless steel mill balls |

From 1mm to 30mm |

|

316l Stainless steel mill balls |

From 1mm to 30mm |

|

Alumina mill balls |

From 1mm-50mm |

|

Zirconium mill balls |

From 0.1mm to 30mm |

|

Agate mill balls |

From 1mm-30mm |

|

Tungsten carbide mill balls |

From 2mm to 20mm |

|

Carbon steel mill balls |

From 1mm to 30mm |

|

Iron core PU mill balls |

From 15mm-30mm |

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)